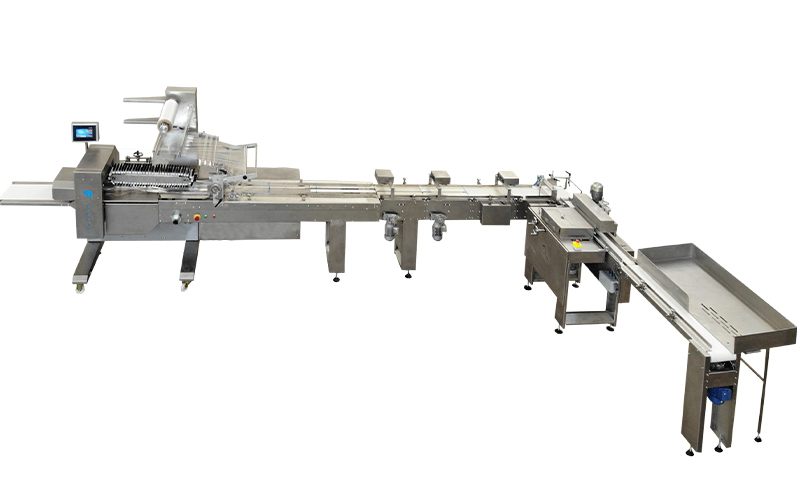

PLC CONTROLLED FULLY AUTOMATIC SEQUENTIAL AND FEEDING HAMBURGER AND SANDWICH GROUP PACKAGING MACHINE

PACKAGING DETAILS

Sealed packaging materials with hot or cold adhesion on one surface, such as cellophane, OPP, and OPP products, can be used as packaging materials. 4-pack, 6-pack, 8-pack (4-inch) – 4-pack, 6-pack (5-inch) Hamburger and 4-pack, 5-pack, 6-pack, 7-pack 60g, 3-pack, 4-pack, 5-pack 110g Sandwich packaging can be done.

CONSTRUCTION

The main frame of the machine is made of food-grade 304 quality chrome construction. The surfaces in contact with the product before packaging are made of food-grade 304 quality chrome. Sliding and hinged closures for complete and easy cleaning, wheeled carrier subframe. Foot for fixed positioning, conveyor support foot.

TECHNICAL DETAILS

Single jaw system (part that seals the package with heat)

Single Coil, double bearing against overload.

Servo-controlled stepless package length adjustment between minimum and maximum values.

Automatic brake system (system that prevents swinging of the packaging roll, ballerina-style)

More durable and professionally designed mechanical system

Automatic package adjustment from the touch screen

Disk printing pneumatic lower adhesive group

Conveyor group adjustable according to the product

During machine operation, stepless jaw speed adjustment between minimum and maximum values.

Adjustable wrapping unit, robust and simple adjustment

Air-tight packaging cellophane coil tightening shaft

Very precise heat adjustment thanks to mercury collectors, trouble-free use for many years.

TECHNICAL DETAILS

Almost zero failure risk compared to other systems (0) delay variator

Protective and safety sensors and systems

Simple and easy use of photocell group

Non-disturbance of adjustment due to the pneumatic structure of the gluing group

Air pressure 5/6 bar

When the machine stops, the heated disk automatically opens without damaging the packaging, no melting, no packaging loss.

Gluing disks can be opened and closed from the screen, and even if left open, they automatically close when the start button is pressed.

It can package products with a maximum size of 26cm width x 50cm length x 10cm height.