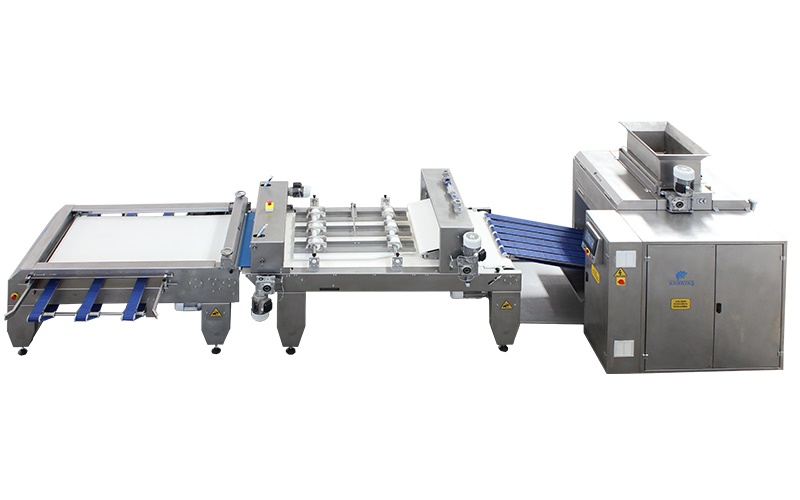

PLC Controlled Fully Automatic 6-Unit Dough Cutting, Weighing, Processing, and Pan Placement Machine

General Features

Electrical and electronic malfunctions of the machine are displayed on the screen as images and notified in text.

The general settings of the machine are done on the touch screen controlled by the PLC (Programmable Smart Control System).

The PLC program of the machine can be reloaded remotely via internet in case of malfunction.

The working parts and belts of the machine are easily detachable and attachable.

The machine is easy to clean.

Our machine is the ONLY one of its kind in Turkey.

The machine is not significantly affected by ambient temperature changes.

All information of the machine is stored in memory and can be used continuously.

The speed settings of all belts in the machine can be adjusted to the desired level.

The machine is easy to learn and use.

Cutting Section

The body and parts of the machine are made of 304 quality Chrome Nickel CRNI stainless steel that does not corrode or tarnish, produced in Finland.

Dough is cut between 30 – 180 grams in the machine.

Max: 11,000 pieces of roll dough are cut and rounded in 1 hour.

(Max: 10,000 pieces of hamburger dough, Max: 7,000 pieces of sandwich dough in 1 hour.)

Very little flour is used in the cutting process, creating a clean working environment.

The amount of flour given to the cut bread dough can be adjusted to the desired amount.

The dough press pistons do not constantly require Kestart food oil during the dough cutting process, the lubrication system is automatically adjusted.

Due to stress-free dough cutting, the dough is not damaged unlike other machines (Stress-Free Dough Feature).

This machine is the main machine for all production lines. With additional units, all types of dough production can be done on this machine.

With the cutting unit, sandwich, hamburger, Cabatta (Ciabatta), Tortilla-Lavash type bread doughs are cut at the desired weight.

Importance of Cutting-Lubricating Oil

Eliminates residue and stickiness in cutting tools.

Extends the machine’s lifespan when using Kestart oil.

Reduces machine maintenance costs.

Kestart oil contains a high percentage of Oleic Acid obtained through refining. Its color is clear, colorless, or light yellow. It is not used directly in food preparation. Contact with food is not harmful to health. It is obtained from olive oil, hazelnut oil, and sunflower oil.

Research has shown that it reduces the risk of high blood pressure by high levels of monounsaturated fatty acids, balances cholesterol, providing protection against heart and vascular diseases. It also reduces insulin requirements in diabetics and has a protective effect against certain types of cancer.