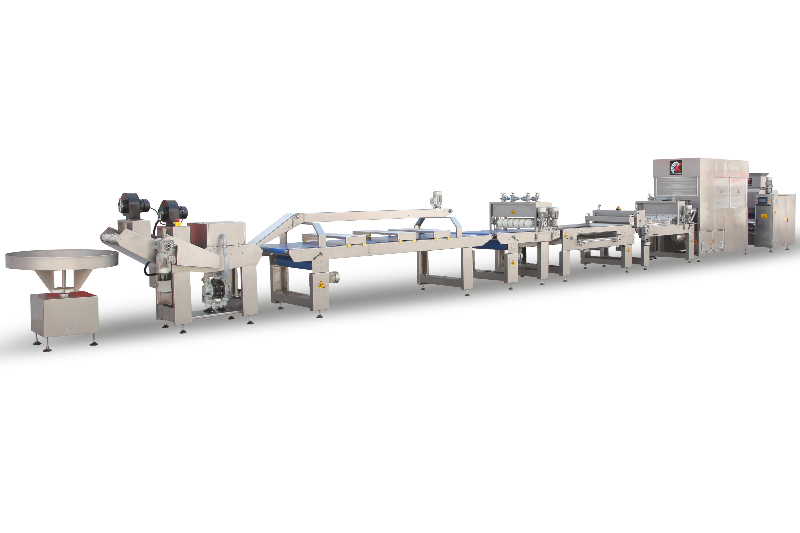

Simits & Pastries, Sandwiches & Hamburgers, Rolls & Baguettes Multi Divider Production Line

General Specifications

All malfunctions of the machine are displayed on the screen as images and indicated in writing.

The overall setting of the machine is done on a PLC-controlled touch screen.

The working components and belts of the machine can be easily removed and installed.

The machine can be easily cleaned.

The machine has a complete assembly and disassembly feature.

Our machine is unique in dough cutting in Turkey.

TYPE: K – LINE 6

MODEL: KRT – HK – SMPH

PRODUCTS MANUFACTURED: Simit-Pastry-Roll-Hamburger-Sandwich-Baguette Bread Varieties

The difference of this line from the Simit & Pastry line is the presence of an automatic tray spreading unit.

CUTTING SECTION

The body of the machine is made of food-grade 304 Chrome Nickel. It is CRNI stainless steel. The machine has six pistons and cuts 6 dough pieces with each stroke. Dough between 30 – 180 grams can be cut with the machine. It cuts and rounds approximately 11,000 dough pieces per hour on average. Due to minimal flour usage during cutting, it creates a clean working environment. The amount of flour given to the dough can be adjusted. The machine does not require constant Kestart oil during the cutting process. Due to the application of low pressure on the dough, it does not cause deformation in the dough.

IMPORTANCE OF KESTART OIL

Eliminates residue and stickiness in cutting tools. Extends the lifespan of the machine when Kestart oil is used. Reduces maintenance costs of the machine. Kestart oil contains a high level of Oleic Acid obtained through refinement. It has a clear, colorless to light yellow appearance. It is not used directly in food preparation. Its contact with food is not harmful to health. It is derived from Olive Oil, Hazelnut Oil, and Sunflower Oil. It has been found through research that it reduces the risk of high blood pressure as a monounsaturated fatty acid, balances cholesterol, and provides protection against heart and vascular diseases. It also reduces insulin requirements in diabetic patients and has a protective effect against certain cancer types.

RESTING PHASE

There are 86 sets of 6-dough carrying cassettes for resting. The total dough basket count is 516. These baskets are made of food-grade polymer material and can be cleaned and removed according to food regulations. Out of these, 70 sets of 6-cassette (420 basket) work while 16 sets of 6-cassette (96 baskets) serve as empty return carriers. The carriers are made of polymer file. The maximum resting time at full speed is 3 minutes. There are transition belts under the resting carriers. When resting is not used, these belts are used to directly transfer the dough from cutting.

SHAPING

In the shaping section, there is shaping, flattening belt, shaping cushion, and sorting unit. The flattening belt is used to give a round shape to the dough. The shaping cushion is used for sandwich-type (long) bread dough. Since this cushion is made of polymer material, it is compliant with food regulations. Product sizes and shapes can be easily adjusted according to the dough weight. In the sorting apparatus, sandwich-type doughs are placed in a single line to prevent them from scattering on the spreading belt, and then all three dough pieces are transferred to the spreading belt simultaneously. This process is controlled by smart eye sensors connected to the PLC.

PROCESSING CONVEYOR

- This conveyor consists of two stacked belts.

- The lower belt can be manufactured between 2 to 6 meters based on the requirement.

- The lower belt is an empty belt with work tables.

- The manual work for shaping simit and poğaça dough from previous stages is done on these tables.

- The final shaped products are placed on the upper conveyor belt.

- The upper conveyor belt is commonly used in simit production.

- Simit binding process is done on this belt, and they are moved to the syrup application section.

- Both belts are made of white PVC and are easily cleanable. Wet cleaning is possible.

- The entire frame of the conveyor is made of stainless steel.

AUTOMATIC PLACEMENT ON TRAYS

The machine automatically arranges various types of dough onto trays or wooden platforms (pasas) of desired sizes. With the machine’s simple adjustments, it can automatically arrange dough onto corrugated and flat trays. If the trays or platforms are not in the proper position, automatic placement stops and an alert is displayed. Special walking belts guide the trays into the placement slot and retract them after placement. If there are no trays in the slot, the placement process does not occur, and the machine stops.

Tray Sizes:

The maximum size for tray placement unit is 80 x 104 cm. Trays of sizes 50×74 – 59×80 – 60×90 – 75×104 – 70×120 are easily accommodated in the Tray Placement Units. Teflon, Aluminum, or specially coated trays can all be used. If a Special Long Tray Placement Unit is requested, it can arrange trays of sizes up to 80×120.

SYRUP APPLICATION UNIT

- The syrup application process for simits from the upper conveyor belt takes place in this section.

- The system consists of a syrup cascade and two fans.

- A lob pump ensures the circulation of the syrup. This pump does not foam the syrup or compromise its properties.

- Simits are transported on a wire belt and pass beneath the syrup cascade.

- There is an overflow section below the cascade, where excess syrup drips, wetting the bottom of the simits.

- Simit then moves onto a second wire belt.

- An air blowing fan on this belt removes excess syrup from the upper surface of the simit.

As simits move to the third belt, they flip over. - Here, any excess syrup from the bottom is drained.

- This minimizes syrup consumption and enhances the simit’s appearance.

- All bearings and components of the syrup application machine are stainless steel.

- Sealing gaskets prevent syrup from leaking outside the machine.

SESAME TRAY

- This unit, used in simit production, is entirely made of stainless steel.

- It consists of a round tray rotating around a central axis.

- Simit from the syrup application unit falls into this tray, and a personnel member mixes them with sesame seeds.