SPECIAL DOUGH LAMINATION AND PROCESSING LINE

TORTILLA & LAVASH PRODUCTION LINE

Although Tortilla resembles LAVAŞ produced in our country, the dough formula that starts the production process is different. This machine produces both Tortilla and Lavash, as well as Yufka Bread.

GENERAL FEATURED

It is a Flour Tortilla Production Machine.

Production in diameters of 18 – 30 cm

Capacity of 10,000 pieces per hour

Press with a capacity to press 16 products in one go

8-unit Cutting Unit

10-minute Dough Resting

Press Dimensions: 1500mm x 1500mm

Heating Element: Resistance with 108 kW power

3-tier Oven, sheet-pallet chain conveyor, natural gas operated

Cooling bands made of plastic modular material. (Habasit brand, with a 100-year warranty)

Product Grouping (Counting) automatically separates into groups of 8-30 pieces.

%100 Karataş patented domestic and national product.

Used metal is 304 Chrome Nickel (CRNI) Stainless Steel from Finland, resistant to corrosion and staining.

Control is through a touchscreen PLC Screen. Remote access via the internet is possible.

A. KESTART

▪ Dough cutting range is 40-110 grams (±2 gr)

▪ 8 dough cutting and rounding in a single operation

▪ Bunker dough carrying capacity is 130 kg

▪ Rounding belt; wet dough band.

▪ Speed control through touchscreen panel

▪ Machine dimensions: 1.9 meters in height, 1.2 meters in width, 1.5 meters in depth.

▪ Electric motors are TC production ELK brand

▪ Reducers are Alfa reducer and Yılmaz reducer

▪ Hourly capacity of 10,000 pieces

▪ Installed power is 5 kW

B. Intermediate Resting

▪ Dough carrying eyes made of polymer material

▪ Carrier body made of AISI 304 stainless steel sheet

▪ Min. resting time is 10 minutes

▪ Chain made of 2″ pitch, steel with pinholes

▪ Main carrier chassis is AISI 304 stainless steel box profile of 60×60

▪ Enclosures made of AISI 304 stainless steel and polycarbonate, non-permeable to heat and air

▪ Operation; synchronized start-stop with kestart

▪ Min. 1680 pieces dough carrying capacity

▪ ELK brand motor, Yılmaz brand reducer

▪ Chain sliders are Habasit brand MB-01 and MB-02, made of polyethylene 1000 material

▪ Installed power is 3.5 kW

C. Tortilla Press

▪ Capacity: 10,000 pieces/hour

▪ 16 products pressed in a single operation

▪ Heating of press plates done with rod resistors

▪ 48 pieces of 2 kW rod resistors are used

▪ Teflon press belt for the press

▪ Printing plates made of aluminum sheet

▪ Motion control with threaded rod domestic servo motor

▪ 4 servo motors of 1.9 kW each

▪ Threaded rod diameter Ø50×10 pitch

▪ Step-step operation of the press belt

▪ Total installed power is 130 kW

▪ Product diameters between Ø18cm and Ø30cm

▪ Precision ±2cm

A. Oven

▪ Loading into the oven will be done by a wire belt onto the oven conveyor.

▪ Cooking is done with a gas burner, direct flame.

▪ Cooking plate is made of 3 mm thick ST52 quality steel sheet.

▪ Cooking plate is transported by a 39.1 mm pitch ear chain.

▪ The oven is three-tiered.

▪ The length of the oven is 4 meters for live cooking.

▪ Single-exit chimney.

▪ Total cooking time is 1 minute.

▪ Total installed electrical power is 15 kW.

▪ The oven combustion system will be reviewed considering natural gas or electricity cost conditions.

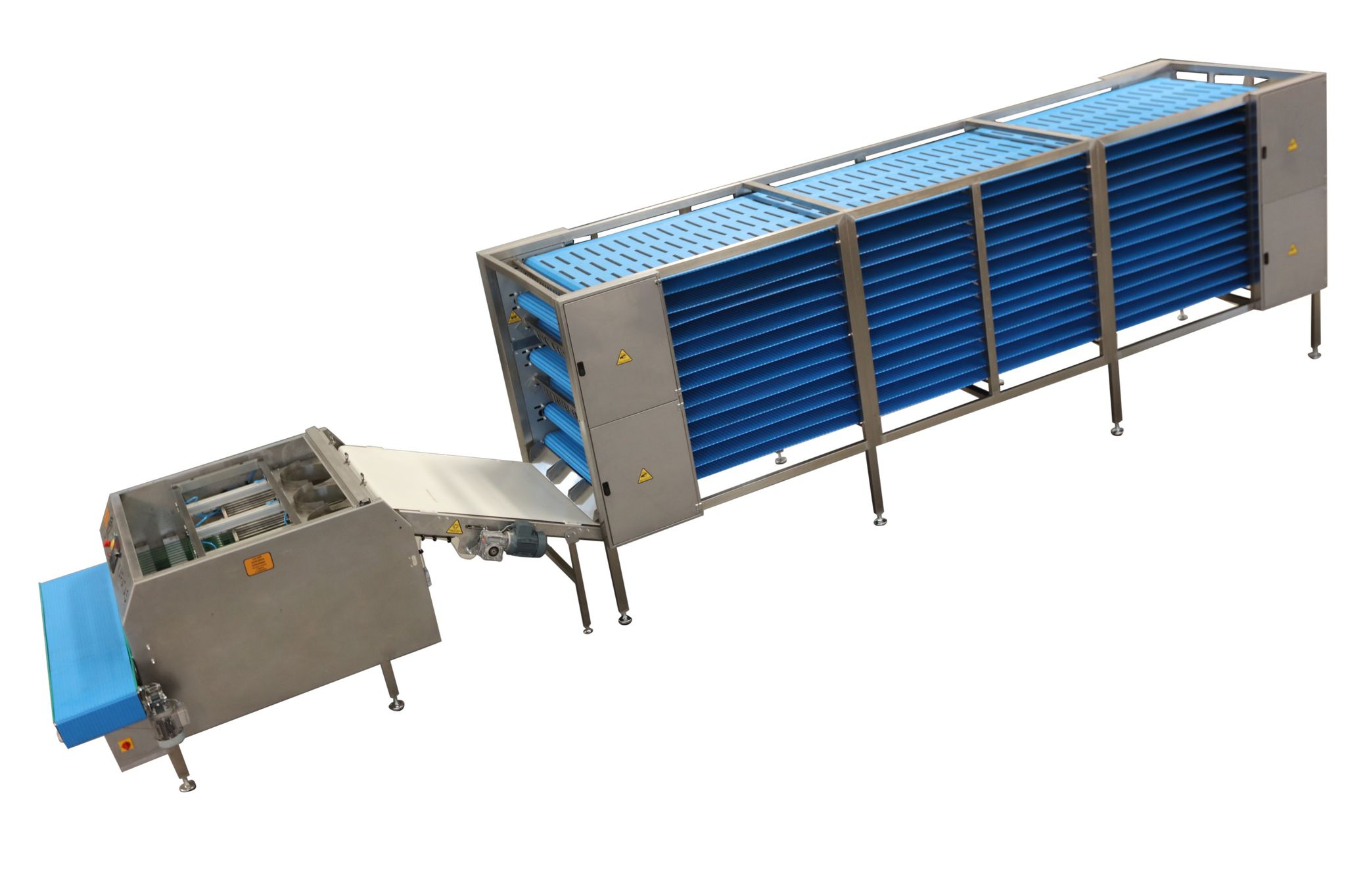

B. Cooling Belts

▪ Cooling belts consist of 9-layer modular belts

▪ Total belt length is 68 meters (Each layer is 7.5 meters)

▪ Belts are Swiss-made by Habasit

▪ Belt width is 1.5 meters

▪ Cooling time is 5 minutes

C. Grouping

▪ Entry belt for grouping is made of silicone with a width of 1.5 meters

▪ It comprises 4 counting units

▪ Utilizes reflective laser sensors for accurate counting

▪ Capable of counting in the range of 8 to 12 units

▪ After counting, each group is pneumatically separated from the system using individual cylinders

▪ O-ring belts are provided by Habasit, a Swiss brand

Technical Specifications

▪ Surfaces in contact with dough throughout the line are made of food-grade stainless steel or polymer material.

▪ Electrical components are of Schneider, a German brand.

▪ Motors are manufactured by ELK, a Turkish brand.

▪ Reducers are of Tramec, an Italian brand.

▪ PLC control with touch panel interface from Delta – Schneider, and similar brands.